Coronavirus, the e-commerce boom and growing competition are changing the old way businesses think about warehouse management. It’s no more just about storing and shipping goods. Logistics players are constantly having to come up with new ways to improve warehouse efficiency to keep up with the competition. Optimize processes, retrain staff, and implement new technologies.

Do you want to know how the use of AI in warehouse management can increase the productivity of your company? Binerals specialists decided to take a closer look at this topic and share with our readers useful information about implementing artificial intelligence in warehousing.

Implement Artificial Intelligence in Warehouse Management

You all already know that AI is being applied in many different areas of our lives, including marketing, training, medicine, and more. But what have you heard about the application of AI in warehouse management?

The picture from the movie where robots manage entire warehouses on their own is partially becoming a reality. Artificial Intelligence in warehousing management is software that specializes in the efficient operation of a facility. What this means: Artificial intelligence will be able to perform the duties of a manager, making decisions on the transportation of goods and analyzing large amounts of data.

For example, Japanese tech giant Hitachi used an artificial intelligence called H to optimize warehouse operations back in 2015. The system watched employees solve problems and memorized the most successful options. Then it drew conclusions and turned the successful ideas into instructions for other employees without any involvement of human managers. This way, even at the experimental stage, the efficiency of the warehouse was improved by 8%. Sounds like something unreal, doesn’t it?

Running a business involves competing with analog enterprises that also aim to succeed. Not implementing artificial intelligence in inventory management means taking a step backward in the competition. Your competitors will be happy to take full advantage of robotic systems and will be able to increase their efficiency many times over.

Want to add artificial intelligence to your warehouse?

Contact warehousesWhich Companies Already Use Artificial Intelligence in Logistics and Warehouse Management?

The best way to be convinced of the relevance and effectiveness of a method is to look at real AI use cases in warehouse management. The use of artificial intelligence in logistics and warehouse management is no exception. Which companies have already managed to implement smart technologies in their business?

- Walmart grocery store chain. This well-known company has recently told the public that it has already managed to implement artificial intelligence for the operation of large warehouses of its company. Of course, major supermarket chains are in great need of such technologies that will help optimize inventory operations.

- One of the most successful and largest companies in the world Amazon. Do you remember when Amazon started out with a small office in a garage? Today, the giant is one of the first to use artificial intelligence to automate the process of packaging online orders. This has a direct impact on how quickly customers from all over the world will receive their long-awaited goods.

- The famous transportation company DHL. Unsurprisingly, this particular transportation company has implemented artificial intelligence technologies to successfully operate its warehouses. The software assists the company’s managers in planning and optimizing inventory operations with parcels.

These are just a few examples of how various business companies have learned how to utilize artificial intelligence in the right field. The warehousing and logistics niche definitely needs the improvement that artificial intelligence can provide.

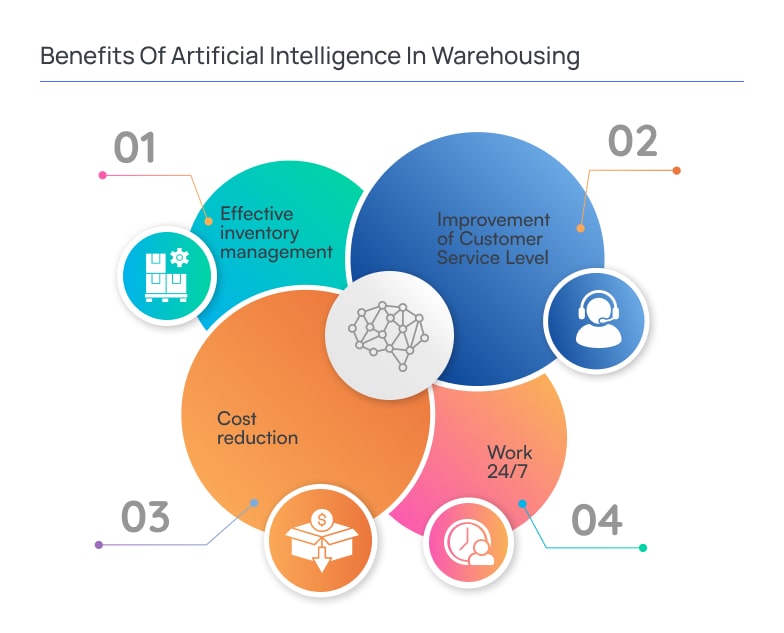

Benefits of Artificial Intelligence in Warehousing

Warehouse management efficiency can increase by 30-40% with the help of artificial intelligence. These are not fictitious figures, as this has already been proven by dozens of companies around the world. We have prepared for you the main benefits of artificial intelligence that will take your company to the next level.

Effective inventory management

Thanks to the accurate operation of artificial intelligence in the warehouse, efficient inventory management can be achieved. The robotic system can independently monitor the goods that are stored in the inventory and the goods that are sold.

Based on the analysis, the AI will easily calculate the required amount of goods in the warehouse. This approach will save you money and protect you from the risks of keeping excessive stock in the storage facility.

Cost reduction

The main objective of every business organization, including logistics companies and warehouses, is to generate maximum profit. This can be achieved by reducing costs. Artificial intelligence can help cut down costs by replacing a certain number of staff. It does not require a salary, unlike humans, and can work around the clock.

Will machines crowd out humans in the warehouses? Automating processes in warehousing will allow logistics companies to perform their functions with fewer staff. Artificial intelligence and robots will undoubtedly change the labor market, and jobs such as packers and baggers will disappear. However, there will be new jobs related to the maintenance of digital systems and robotics. In the near future, professions such as:

- AI data management specialists.

- Robotics engineers and maintenance technicians.

- Cybersecurity specialists.

In any case, it will be much more profitable for a company to implement artificial intelligence in inventory management than to pay salaries to dozens of employees every month. Interestingly, one artificial intelligence can replace 10, 20, or even 100 employees in a warehouse.

Work 24/7

Artificial intelligence does not need to rest and can work at any time of the day. This benefit is very important for warehouse operations, as large storage facilities operate both day and night. All that AI requires is regular maintenance and updates. But how exactly does the continuous operation of artificial intelligence inventory management?

- Continuous control and monitoring. AI in inventory management can track status, monitor storage conditions, and analyze the flow of goods around the clock without the need for breaks or days off.

- Increased productivity. Working non-stop, AI systems are able to process orders in real time, reducing the time from order entry to fulfillment.

- Reduced time for problem-solving. AI is able to react instantly to problems that arise, whether it’s a delayed delivery, equipment malfunction, or an error in an order.

By implementing artificial intelligence in the warehouse, you get one multifinancial employee who works without lunch breaks and without weekends.

Improvement of Customer Service Level

What is the dream of every customer of any online store? That’s right – to have their order arrive safely at their door as soon as possible. AI warehouse management helps optimize internal processes and increases customer satisfaction. By accurately forecasting demand and optimizing ordering and delivery processes, customers receive their orders faster and with less chance of errors. Thus, customers will be satisfied with your services and are more likely to come back to you more than once.

We should also mention that artificial intelligence can easily analyze customer purchase data, preferences, and behavior. This allows you to offer them personalized recommendations and personalized offers. To build an AI chatbot is a great solution for every business.

How Can AI Improve Warehouse Management?

Top managers of large corporations quite often face the problems of inefficient inventory management, high inventory balances and slow work. All these problems are the responsibility of the company’s management and sometimes even cause major losses. Real professional managers always keep an eye on the latest technologies that can make the work easier and faster. The best solution today for top warehouse management is to pay attention to artificial intelligence and apply it.

You may ask why to implement machine learning in warehouse management if this department is already running smoothly. Even if your business is thriving, there are no definite limits to success. Artificial intelligence warehouse management can improve speed of operation, inventory performance, and more. We’ll share more about how AI can improve warehouse management nowadays.

Process Automation

No matter how fast a human can work, the speed of his work cannot be compared to artificial intelligence. Smart systems can automate various inventory and logistics processes. This can include shipping goods, moving around the warehouse, maintaining documentation and other work tasks that workers encounter every day.

Automated order management systems based on artificial intelligence use sophisticated algorithms to automatically track orders, monitor delivery times, and identify any potential issues that could lead to delays.

Artificial Intelligence Predictive Analytics in Warehouse Management

Remember a few years ago when the whole world instantly went crazy over spinners? In 2017, this simple mechanical toy captured the minds of children and some adults. Thanks to such great popularity, the demand for spinners suddenly increased many times over, but an acute shortage was avoided. Few people know, but the situation was saved by artificial intelligence. According to a report by the international transportation company DHL, the algorithm was able to accurately predict the demand for spinners based on the dynamics of viral video views and search queries. Thus, suppliers got a small head start and prepared additional batches of toys.

In the context of inventory management, predictive analytics serves as a powerful product management tool. With the help of data, the algorithm can effectively predict demand spikes, allowing the accumulation of product stocks in demand in advance. Or, on the contrary, successfully get rid of goods that nobody needs. The example with spinners demonstrates how unpredictable demand can be – it depends on trends and popularity. Therefore, having artificial intelligence in warehousing is simply an indispensable tool in 2024.

Safety Assurance

Many enterprise owners often wonder if it is safe to implement artificial intelligence in their warehouse management. They fear that AI can leak data into the public domain. In fact, this is not the case at all. On the contrary, artificial intelligence will provide your business with a higher level of security for handling confidential data.

Another important point is that artificial intelligence can be programmed to identify all sorts of potential threats. For example, when a program flags an external risk, planners can send an email to suppliers (also using AI) so that they can warn and mitigate potential disruptions. The supplier, in turn, can respond to the email if it deems the prediction significant and further regulate cooperation according to the AI data received.

Data Collection and Factor Tracking

What else can a smart system do to help manage storage facilities of different sizes? It will collect data and track what potential risks may happen on the path of goods from point A to point B. Weather, geopolitical tensions, financial risks, traffic jams at borders, strikes – these and other potential troubles AI will track in the news, collect the information together, analyze, and send a message to the manager. According to experts from the industry, this will help plan supply chains more efficiently and optimize the work of logistics company employees.

Looking for a way to incorporate machine learning in inventory management?

Contact our teamSum Up

Organizations that use robots and artificial intelligence in warehouses are becoming more competitive and growing faster. There is already a lot of real-world evidence of this fact, where AI has been able to improve the efficiency of inventory management. Some operators are already modifying their warehouses to make better use of the new capabilities in the long run.

If you want to make your storage facilities state-of-the-art and use AI inventory management as soon as possible, you should trust the professionals. Binerals is a company that knows how to help with logistics software development services and the implementation of artificial intelligence in warhouse.

FAQ

Which warehouses would be suitable for implementing artificial intelligence in their operations?

It doesn’t matter how big your company is or what it actually does. If you store goods, pack them and deliver them to customers, you can count on artificial intelligence to help you significantly. These technologies can be applied to small, medium and large warehouses alike.What can artificial intelligence do to improve warehouse efficiency?

Artificial Intelligence is ready to perform dozens of functions to make it easier to manage the storage facility. One of the main functions is data analysis and forecasting to ensure optimized inventory operations. The software can help you forget about what it’s like to have a large inventory of unnecessary items in your warehouse. It can also even train your employees, build the most optimal routes for logistics companies, and make important decisions quickly.What challenges can I face when implementing artificial intelligence in inventory management?

Despite all the pros of artificial intelligence in inventory operations, there are several reasons that can make it difficult to implement the software quickly and efficiently. For example, many companies are already using various warehouse management programs and this can prevent the addition of artificial intelligence. Another difficulty is employee training. It can take some employees a long time to learn how to work in tandem with robotic systems in the warehouse.